The self-developed UV-SIL™ active alignment adhesive from Sil-More industrial Ltd in Taiwan. Which refer to a continuous shrinkage monitoring method from ISO 4216 (International organization for standardization) and JIS K6941 (Japanese industrial standards), to improve production efficiency in active alignment adhesive process. This analysis can measure the volume change of curing, it’s precision can achieve to micrometers and detected in milliseconds.

【Features】

1、Low shrinkage, precise alignment apability.

2、VOC-free, compliant with GB 33372-2020.

3、High glass transition temperautre, stable at elevated temperatures.

4、Low thermal expansion coefficient, adaptable to temperature variations.

【Application】

Materials for manufacturing processes in electronics, optics, medical devices, automotive components, and other industries.

【Case】

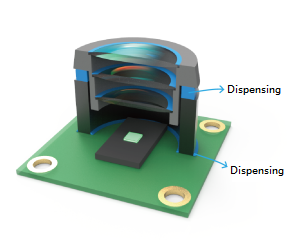

In the active alignment process for lens modules, the shrinkage of the adhesive directly affects the imaging quality of the camera module. However, emphasizing high productivity makes it challenging to wait for the adhesive to reach shrinkage equilibrium for an extended period. UV-SIL™ Active Alignment Adhesive uses a continuous shrinkage analysis method to predict the shrinkage and expansion trends, reducing process uncertainties and enhancing production efficiency.