Fiber Reinforced Thermoplastics (FRTP) feature high toughness, excellent impact resistance, short manufacturing cycles, and outstanding chemical resistance. Additionally, they can be processed repeatedly, making them an essential material for the development of innovative and unique products in various industries.

The Sil-More Group collaborates with partners in the electric vehicle supply chain to jointly develop numerous applications of thermoplastic composite materials. The materials have undergone rigorous verification by automotive manufacturers for UL 94 5VA (flame resistance), UL746 C f1 (weather resistance), and IEC (safety), bringing a safer, lighter, and more integrated composite plastic solution to the electric vehicle industry.

「Charging Gun」

Characteristics:Scratch-resistant, impact-resistant, flame-retardant,

heat-resistant, weather-resistant.

Materials:PA6/66+25%GF、PC/ABS、PC/PBT、TPE

Application:Handle, plug, charging gun casing

「Charging Station」

Characteristics:EMI shielding, flame resistance, color appearance,

weather resistance

Materials: PC/PBT、PA、PC、PC/ABS、PC/ASA、ASA 、TPE

Application:Charging station casing, external panel, charging cable

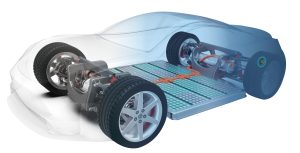

「Electric Vehicle」

Characteristics:EMI shielding, flame retardant, thermal conductivity,

lightweight, durability, weather resistance.

Materials:Si-PC、PA/66、PC+PBT、ASA、TPU、LCP

Application:Vehicle electrical systems, battery systems, body systems.